Creo Complete Mold Design, Improve Efficiency and Productivity of Mold Design and Tooling

Download a 30-day Trial of Creo 7.0!

By form submission, you agree to the Terms of Service

ABOUT

Creo Complete Mold Design:

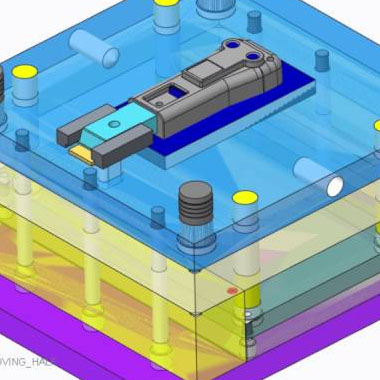

Specialized Mold Assembly Creation!

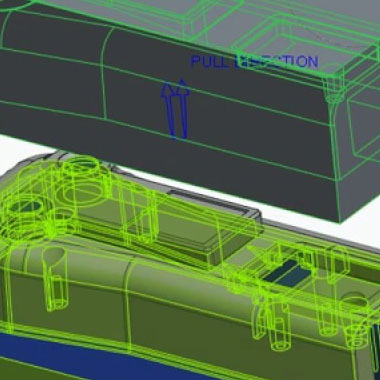

Mold design is the analysis, design, and refinement of molds for industrial manufacturing. Molds must be able to form the solid part out of the molten material, cool the part so it can solidify, and eject the part from the mold. The list of ways in which a mold can fail to accomplish these purposes is long and vivid.

It's not surprising that mold design has a critical impact on the cost-effectiveness and quality of molded parts and thus of your product. A bad mold can give you that sinking feeling in more ways than one.

If you’re looking to accelerate moldbase design and find more time to development better quality, highly innovative designs, then this is your perfect solution. Put Creo Expert Moldbase to work for you.

-

OPTIMAL DESIGN

OPTIMAL DESIGN

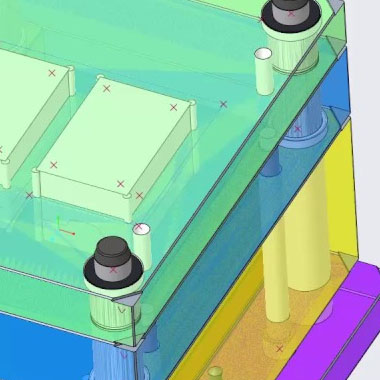

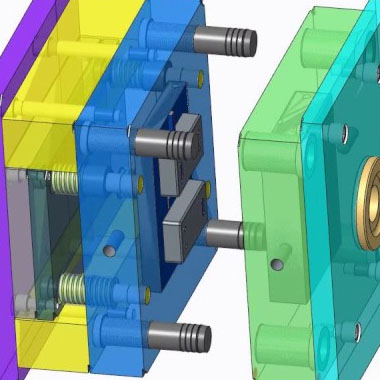

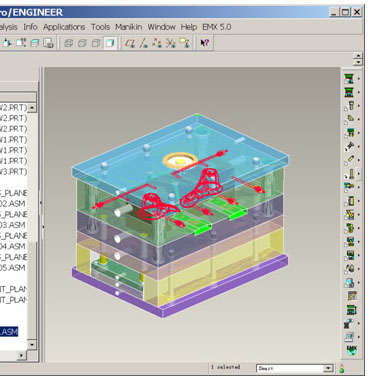

Create moldbase layouts in a familiar 2D environment and automatically generate a 3D model to leverage the benefits of 3D design. The 2D process-driven GUI guides you toward your optimal design and updates automatically during the development of the moldbase. The resulting 3D models are then used for interference checking during mold opening.

-

UNIQUE INTERFACE

UNIQUE INTERFACE

PTC Creo EMX increases design speed because the unique graphical interface gives you quick, real-time previewing before the 3D component or assembly is automatically placed. Once your components are placed, operations such as clearance cuts and drilled and tapped holes are automatically created in the appropriate neighboring plates and components.

-

WELL DOCUMENTED

Features

Creo Complete Mold Design - Familiar Moldbase Environment

Images & Videos

Examples Using Complete Mold Design

Select Category

-

Speed Design

Speed DesignSpeed design through simple, process-driven workflows to automated moldbase design and detailing.

-

Libraries

LibrariesIncludes libraries for 17 moldbase/component suppliers (e.g., screws, ejector pins, sliders, cooling fittings).

-

Functionality

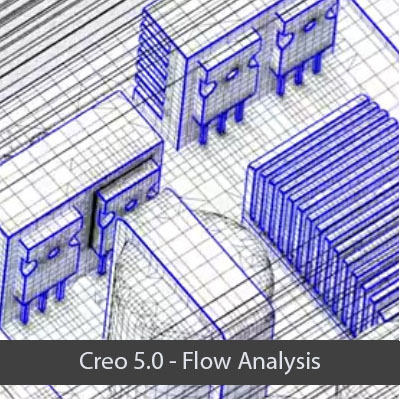

FunctionalityAutomatic ejector pin, waterline, and fittings functions, automated runners and waterline checks.

-

Reduce Cycle Time

Reduce Cycle TimePrevents costly rework and reduces cycle time by eliminating mistakes, via a 3D environment.

-

Automatically Update

Automatically UpdateReduces the need for redesigns by automatically updating tooling models, drawings and electrodes.

-

-

-

-

-

See More Videos on Creo Products